Previously, Malaysia imposed anti-dumping duties on steel imported from Vietnam at rates ranging from 7.70% to 20.13% for 5 years

Reducing dependence on imported raw materials, localizing supply sources and recycling technology are the keys to success for Vietnamese aluminum enterprises from 2025.

In the context of the Vietnamese aluminum industry continuing to have stable development steps with output in 2024, increasing by 14.5% compared to the previous year, experts in the field shared multi-dimensional perspectives on opportunities and challenges for domestic aluminum manufacturing enterprises.

Positive signs mixed with challenges

Sharing at the recent workshop "Non-ferrous metal industry and applications - Connecting China - Vietnam trade", Mr. Nguyen Minh Ke, Chairman of the Vietnam Aluminum Profile Association (VAA) shared the panoramic picture of the aluminum industry with extremely impressive numbers.

Accordingly, the total aluminum output of the whole industry reached 1,127,853 tons in 2022, although there was a decrease to 1,028,205 tons in 2023, but it recovered to 1,239,910 tons in 2024.

“These figures demonstrate that the aluminum industry is gradually asserting its position in the industrial value chain, although there are still many challenges in ensuring stable supply and competitive prices,” Mr. Ke commented.

According to forecasts, the size of Vietnam's aluminum market will reach 4.53 billion USD by 2025 and may increase to 7.3 billion USD by 2030. One of the main drivers for this growth is the construction industry, which accounts for 38% of total aluminum demand.

Construction is the industry with the highest total demand for aluminum, helping the aluminum industry affirm its position in the industrial value chain. Illustration: Hoang Anh

Vietnam’s aluminum industry is mainly distributed to sectors such as construction, packaging, transportation and electronics. Forecasts show that with large infrastructure projects in Vietnam, the construction industry will continue to be the main pillar driving demand for aluminum in the coming years.

However, Mr. Ke also noted that the industry is still facing significant challenges, especially the dependence on imported raw materials, almost 100%, mainly from countries such as China and Germany, as well as pressure from price fluctuations in the global market.

In addition, the aluminum industry is also facing a situation of excess production capacity, with current operating capacity ranging from 40% to 70% in the context of the global economy not fully recovering. Trade defense measures from other countries are also a challenge for the export activities of the Vietnamese aluminum industry.

The phenomenon of " origin laundering " is also a burning issue, as many foreign manufacturers take advantage of this to export aluminum products of Vietnamese origin. This not only damages the reputation of the industry but also entails serious legal risks.

Localizing raw materials – Proactive solution for the industry

One of the issues most mentioned by experts is the over-reliance on imported raw materials.

In that context, domestic enterprises are making efforts to transform production models by promoting the application of aluminum recycling technology.

The aluminium industry is currently showing tremendous growth with booming demand from industries such as construction, automobile manufacturing and electronics.

Self-sufficiency in raw materials and application of recycling technology are decisive factors for stability and sustainable development .

Businesses are gradually shifting their focus to investing in modern aluminum recycling systems with the goal of accounting for about 20% of total aluminum extrusion production. This not only reduces dependence on foreign supplies but also helps stabilize product prices, creating favorable conditions for forecasting and risk management.

Applying recycling technology and being self-sufficient in raw materials are decisive factors for the stability and sustainable development of Vietnam's aluminum industry. Illustration photo: Hoang Anh

“We are witnessing a clear shift in trend, as businesses step up aluminium recycling to reduce their dependence on imported raw materials. Increasing aluminium recycling capacity is not only an economic solution but also an important step towards environmental protection.

Enterprises need to invest in modern technology to convert raw materials, help reduce production costs and increase competitiveness in the international market," said Mr. Vu Van Phu, Vice President of VAA.

This is also a message that domestic enterprises need to keep in mind, as the trend of green production and CO2 emission reduction is increasingly being prioritized by demanding markets such as the EU and the US.

The trend of “green production” and the application of modern technology, including the integration of automation systems and quality control using AI, is a necessary direction for businesses to not only maintain but also improve their position in the market, Mr. Phu emphasized.

In addition to optimizing production processes, close links between domestic enterprises will help create a strong supply chain, limiting risks from fluctuations in imported raw material prices. At the same time, according to Mr. Phu, cooperation and integration with strategic partners in the region will open up many opportunities to access large markets, especially dynamic markets like Asia.

Investing in self-sufficient primary aluminum production technology is considered a strategic direction, promising to bring competitive advantages to domestic enterprises when facing competition from foreign investors.

Competitive pressure from FDI and opportunities to expand export markets

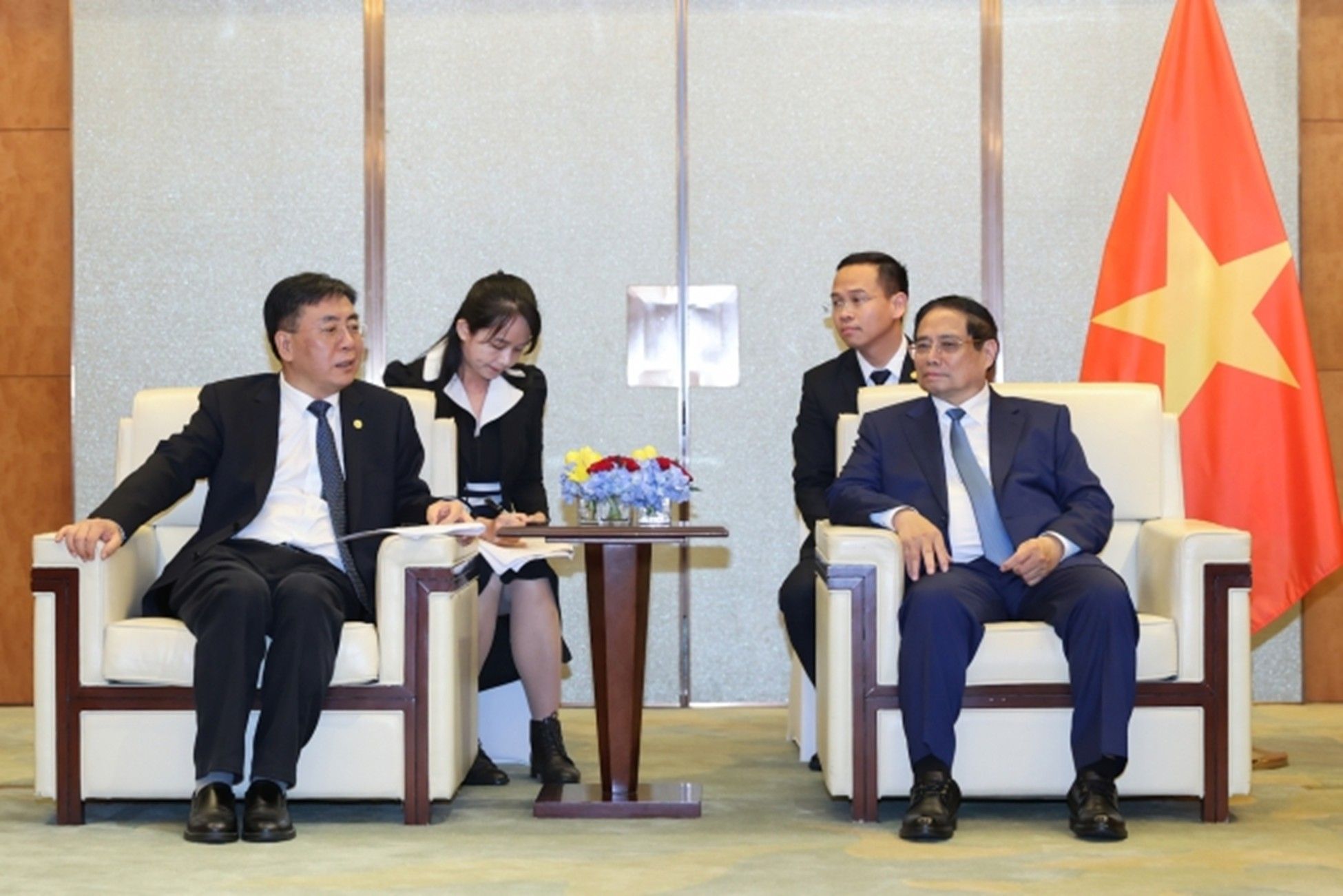

According to Mr. Lu Jian, Deputy Secretary General of the China Nonferrous Metals Industry Association (CNFA) and Mr. Nguyen Van Toan, Vice President of the Vietnam Association of Foreign Direct Investment Enterprises (VAFIE), Vietnam’s aluminum industry is facing fierce competition from foreign direct investment (FDI) enterprises, especially from China. At the same time, the opportunity to expand export markets also comes with challenges in terms of international trade standards and policies.

FDI enterprises have strong financial potential, possess modern production technology and operate on a large scale, which helps them optimize costs and improve productivity.

If domestic enterprises do not quickly upgrade technology and optimize processes, they may have difficulty maintaining market share in the domestic market.

Mr. Lu Jian commented that FDI enterprises, especially from China, are increasingly increasing their presence in Vietnam thanks to their advantages in advanced production technology, large investment scale and the ability to optimize the supply chain. According to him, this poses two impacts on the domestic aluminum industry.

On the one hand, the participation of FDI enterprises brings technology transfer, helping Vietnamese enterprises have the opportunity to access modern production techniques, optimize processes and improve product quality. In particular, automation systems and AI quality control technology are becoming important factors to help improve productivity and reduce production costs.

FDI enterprises will bring many advantages to help domestic enterprises access modern production techniques, optimize processes and improve product quality. Illustration photo: Hoang Anh

On the other hand, competition between domestic and FDI enterprises is becoming increasingly fierce. “Foreign-invested enterprises not only have strong financial potential but also have the ability to effectively exploit supply chains and large-scale production systems. If domestic enterprises do not quickly upgrade technology and optimize costs, they will risk being overwhelmed in their own home market,” Mr. Lu Jian emphasized.

Sharing the same view, Mr. Nguyen Van Toan also pointed out that the wave of investment from China not only brings cooperation opportunities but also poses significant challenges for Vietnamese enterprises.

“Chinese enterprises have a big advantage when investing in the aluminum industry thanks to competitive production costs and supportive policies from both countries. However, this also leads to the risk of domestic enterprises being disadvantaged, especially if they have not had time to innovate technology and improve management capacity,” said Mr. Toan.

In addition, Mr. Toan noted that increased investment from foreign enterprises could lead to an imbalance in the industry, as domestic companies risk becoming dependent on capital and technology from FDI instead of proactively developing their own production capacity.

Despite facing competition from FDI enterprises, according to Mr. Lu Jian, Vietnam's aluminum industry still has many opportunities to expand exports, especially when taking advantage of free trade agreements such as EVFTA, RCEP and CPTPP.

Mr. Lu Jian noted that Vietnamese enterprises have advantages thanks to competitive production costs, but to truly reach out to the international market, meeting environmental and technical standards is a prerequisite.

“Trade barriers, especially the European carbon tax and the US trade protection policy, will impose strict requirements on exporting enterprises. Investing in green production and reducing carbon emissions will not only help enterprises overcome these regulations but also create a competitive advantage when accessing high-end markets,” said Mr. Lu Jian.

Another notable trend is the shift in global supply chains, as international corporations seek new sources of supply outside of China. This could be an opportunity for Vietnamese aluminum enterprises to join the supply chains of major brands, if they are well prepared in terms of quality and production technology.

In general, to maintain its position in the domestic market as well as expand internationally, Vietnamese aluminum enterprises need to proactively innovate technology, build sustainable supply chains and meet increasingly stringent environmental standards.

(Source: Diendancuacacnhaquantri)

--

Oristar – Leading Metal Supplier in Asia

⚡ Core product lines: Copper, Aluminum, Steel

⚡ Main product grades provided by Oristar: Aluminum alloys, Copper alloys, Aluminum alloy plates, Aluminum coil grades, Tool steel, Special steel: A5052, A6061, A7075, C1100, C2680, C3604, SUS303, SUS304, SKD11, SKD61,...

For product consultation, please contact:

⚡ Hotline: 0988 750 686

⚡ Email: info@oristar.vn

⚡ Zalo OA

⚡ ️Website E-commerce

⚡ Official Website

VN

VN

EN

EN

KR

KR

JP

JP

CN

CN

Economy

Economy