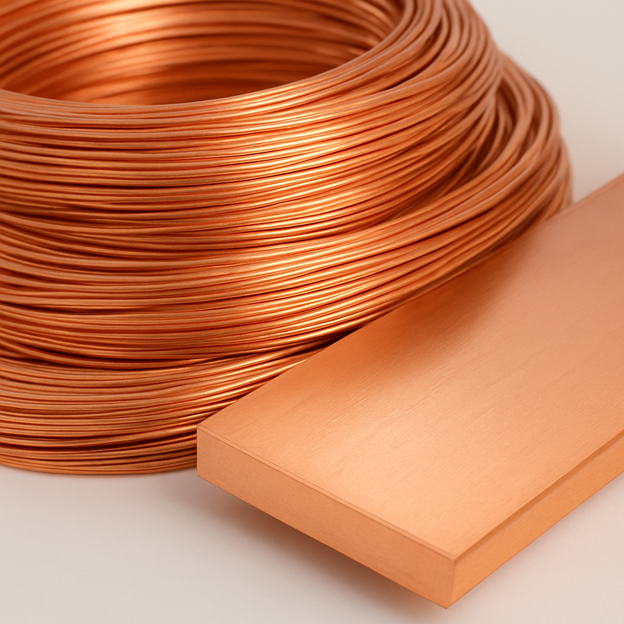

Copper is a valuable non-ferrous metal in industry and commerce due to its good electrical and thermal conductivity, high mechanical strength and corrosion resistance. However, to ensure that copper quality always meets standards during storage and use, businesses need to conduct proper inspection and preservation. The following article will provide detailed instructions on how to check copper quality and preserve copper effectively to avoid loss of value and maintain product performance.

How to check copper quality

Copper quality testing should be performed periodically and before production. Some common methods include:

Visual inspection

- A shiny surface, without black spots or rust is a sign of pure copper.

- If you notice a green or gray oxidation layer, it may be a sign of corrosion or improper storage.

Check chemical composition

- Using a spectrometer to analyze elemental composition helps determine %Cu and impurities such as Zn, Pb, Sn...

- Industrial quality copper usually has a copper (Cu) content of 99.9% or more .

Physical and mechanical testing

- Conductivity : can be measured with an Ohmmeter, high conductivity proves pure copper.

- Hardness and ductility : use mechanical testing equipment such as tensile and compression machines to ensure mechanical strength meets production standards.

Check with documents, origin

- Check quality certificates (COA, CQ) from reputable suppliers.

- Verify the origin to ensure copper is mined and refined according to international standards.

How to preserve copper effectively

Copper is susceptible to oxidation when exposed to moisture, air or chemicals. Proper storage will help extend the life and maintain the value of copper in storage or during transport.

Environmental storage conditions

- Stable temperature, low humidity (<60%).

- The warehouse must be airy, clean, away from direct sunlight and corrosive chemicals.

Wrapping and packaging

- Use oil paper, PE film or vacuum bag to wrap the copper surface.

- Avoid letting copper come into direct contact with the warehouse floor. It should be placed on a dry, clean wooden pallet .

Streamlined

- Classify by type, size, batch code .

- There are clear signs about the date of import, source of supply, quality.

Periodic check

- Schedule weekly or monthly inventory checks .

- If slight oxidation is detected, specialized chemicals can be used to clean and disinfect .

Notes on transporting and processing copper

- Always use specialized packaging , avoid impact or scratching the copper surface.

- Before processing (cutting, sawing, milling, welding, etc.), it is necessary to re-check the thickness, hardness and original structure of the product to ensure no deformation.

Conclude

Testing and maintaining copper quality is a key factor to ensure performance and stability in the production process. Enterprises need to build a strict control process from the import, storage to transportation and use. If you are looking for a reputable copper supplier with a standard inspection and preservation system, Oristar is always ready to accompany you.

Contact Oristar now for a free quote and technical advice.

--

Oristar - Cung cấp kim loại hàng đầu khu vực Châu Á;

⚡ Các dòng sản phẩm chính: Đồng, Nhôm, Thép;

⚡ Các mã sản phẩm chính Oristar đang cung cấp: nhôm hợp kim, đồng hợp kim, nhôm tấm hợp kim, nhôm cuộn mác, thép công cụ, thép đặt biệt: A5052, A6061, A7075, C1100, C2680, C3604, SUS303, SUS304, SKD11, SKD61,...

Quý Khách hàng cần tư vấn về sản phẩm vui lòng liên hệ:

⚡ Hotline: 0988 750 686

⚡ Email: info@oristar.vn

⚡ Zalo OA

⚡ ️Website E-commerce

⚡ Official Website

VN

VN

EN

EN

KR

KR

JP

JP

CN

CN

Copper

Copper